| Many museums are closed

on Mondays and public holidays so we had to wait until Tuesday. This was a

rare time when Jan and I went our separate ways: she went to a quilt museum

which had just moved to a new building on the University of Nebraska campus.

The art outside seems to represent the random quilting lines used in many

quilts - but I could be wrong. |  |

|

Unfortunately, but not unexpectedly, photography is not permitted. The

museum has a policy of themed displays so, rather disappointingly, most of

the quilts are not on display. However the whole collection has been

photographed and can be seen 'virtually' by using the museum's computers. |

| I wandered deeper into

University territory past this collection of dishes. Two of the largest are

for PBS (Public Broadcasting Service) and Ag-Comm. They are a reminder of

the fact that most of the public broadcasting in the US is managed and

transmitted by the universities. |  |

|

I was headed for the Larsen Tractor Testing Laboratory and Museum,

home of the only tractor performance certification centre in the US. Testing

started in the US in 1919 after W F Crozier, a Nebraska congressman, bought

a tractor which did not live up to the salesman's promises. |

| The collection contains

more than just tractors, starting with horse and oxen drawn implements. This

is the famous plough which started John Deere on the road to fame and

success. |  |

|

This is the tractor that started it all. Needless to say, the company long

since went out of business. It is a 1909 Ford 8-16hp tractor. The company

hoped to capitalise on the Ford name by employing someone called Ford. The

Ford company brought out its first tractors under the name Fordson in 1918. |

| There are some

interesting items of equipment but here the tractor is of more interest. It

was one of the first to have a three point linkage enabling equipment to be

added. |  |

|

There are three and four wheel tractors with every conceivable size of wheel

and tyre and even some with tracks. These were much favoured on softer land

since they did not sink in so easily. |

| This tractor looks odd

because the engine is actually mounted behind the main wheels giving the

driver a much better view of the crops he was tilling. |  |

|

This is a tractor test and demonstration rig used for work on tractor

rollover experiments. Tractors overturning was once a major cause of deaths

in the farming community. |

| Another way of coping

with soft and wet soils was the unusual wheels fitted to this tractor. The

twin wheel arrangement at the front was very common between the wars. |  |

|

The Farmall tractor was once the commonest tractor in the west. |

| This model T pickup is

also on display. It was used between 1925 and 1936 by a university geology

student on his field trips. |  |

|

I'm not sure that they were all used on tractors but it is remarkable that

there should have been so many variants of such a complex part of the engine. |

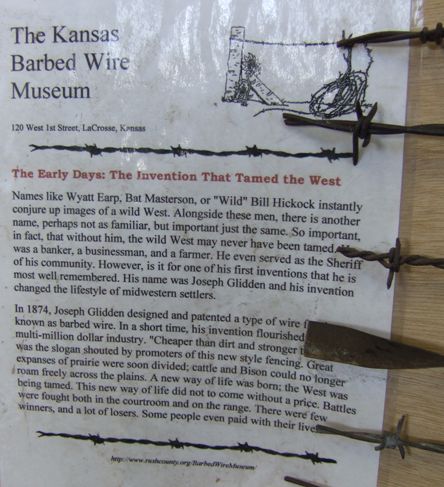

| Just as an aside there is

a mention of the Kansas barbed wire museum and a small collection of barbed

wire. We went near that museum in 2005 but didn't visit. We feel we probably

should have done. |  |

|

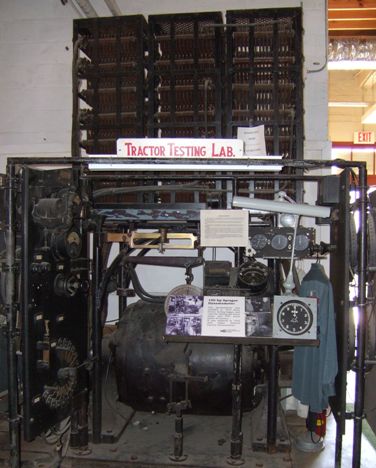

The early test dynamometer used to measure the power output of the tractor.

Fuel consumption was measured at the same time by weighing the remaining

fuel every few minutes. |

| The tractors in the

museum are mostly less than 20hp and they stopped collecting before diesel

engines came into common use. These are three modern 500hp tractors waiting

to be tested in the coming week |  |

|

And the modern test dynamometer car was standing on the oval track at the

back - sadly they weren't testing outside today. |

An interesting point came up while talking to the docents in the museum: as a

result of research at the university, many farmers in Iowa and Nebraska no

longer plough their fields but merely harrow them with the stubble still

present, and then sow the seed followed by chemical sprays to control weeds.

Thus they use heavy equipment on the fields only three times (the last being to

harvest). This apparently works very well and leads to less erosion and

compaction of the soil and better drainage and water management, important

features with water usage becoming more critical and fuel costs rising

exponentially. Big tractors can use 1000 gals of diesel per day. |